NEWS CENTER

Specially developed and developed high-end polyoxymethylene (POM) / long-fiber materials (PP.PA.TPU, etc.) in automobiles, electronic appliances, fasteners, sanitary, military, aerospace, marine, office supplies, agricultural irrigation, electronic appliances, etc.

If... No engineering plastics in the automotive industry? That's impossible!

- Categories:Media coverage

- Author:

- Origin:

- Time of issue:2018-12-13 09:46

- Views:

(Summary description)Engineering plastics has changed the automotive industry and will continue to have a huge impact on future automobiles...

If... No engineering plastics in the automotive industry? That's impossible!

(Summary description)Engineering plastics has changed the automotive industry and will continue to have a huge impact on future automobiles...

- Categories:Media coverage

- Author:

- Origin:

- Time of issue:2018-12-13 09:46

- Views:

Engineering plastics has changed the automotive industry and will continue to have a huge impact on future automobiles. In the 1950s, plastics accounted for 1% of the value of automobiles. Today, plastic accounts for nearly 35%. By 2030, this number is expected to grow to 50%, because designers have found more places to replace plastics in power systems, interiors, exteriors, engine systems and other fields, they can convert metals to plastics, weight Reduced by 40% to 50%. Although weight reduction may be small at the level of individual components, the cumulative effect is significant. To help you imagine a world where plastics are not used for automobiles at all, let's look at an example calculation of the cumulative effect of a lighter weight vehicle.

Engineering Plastics--Environmentally Friendly

Medium-sized cars weigh an average of 1.5 metric tons. By weight, plastics in cars now account for about 10% to 12%. Let us assume that the vehicle is made of 12% plastic, then parts made of plastic are reduced in weight by 45%. Engineering plastics enable a medium-sized vehicle to save 150 kilograms of weight, which is equivalent to reducing fuel consumption by 0.75 liters / 100 kilometers and reducing carbon dioxide emissions by about 15 grams / km.

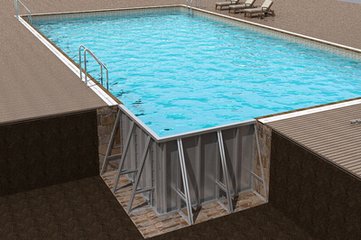

Save fuel on nearly 40,000 swimming pools

Now let us reduce the weight of the 1 billion passenger cars on the roads around the world. The combination of weight / fuel savings of these vehicles can be achieved. The average distance traveled by each vehicle is 13,000 kilometers per year, which can save 97.5 billion liters of fuel per year, which is enough to fill nearly 40,000 Olympic-sized swimming pools.

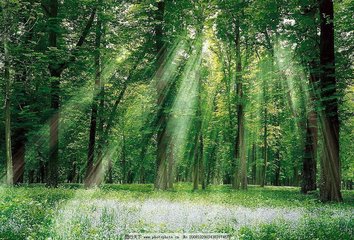

The forest area required is about five times that of Guangdong

The reduction in carbon dioxide emissions is also significant. This collective fuel saving results in a reduction of 19.5 billion kg of carbon dioxide annually, which is equivalent to the total amount of carbon dioxide emissions generated by the annual electricity consumption of 29.2 million households. Without plastics in cars, 930,000 square kilometers of forest are needed to isolate the additional carbon dioxide generated by fuel emissions. The forest area is twice that of California, three times that of Italy, five times that of Guangdong Province, and South Korea Nine times the area.

Safety performance of engineering plastics

In addition to the significant contributions made by engineering plastics in reducing vehicle weight and fuel consumption, they also help us improve vehicle safety through new safety features, reduce component failures, and improve electrical performance, because today's cars are close to complete Electronic fully automatic vehicles.

Weight loss goals for engineering plastics

DSM's product portfolio includes various material grades, specifically designed for the specific conditions of various automotive applications. For applications such as chain tensioners, MTD parts, gears, charge air cooler end caps, turbine ducts, front-end modules, firewalls and pedals, DSM materials can help designers significantly reduce weight while still being able to withstand Extreme conditions of use. This includes resistance to high temperatures, humidity and chemicals without losing material-level performance. DSM's new generation of materials, the proposed solution will help to further reduce the weight of the vehicle. Original equipment manufacturers strive to achieve an average reduction of 200 kg in vehicle weight required to meet the 2025 emissions target.

DSM solutions

Arnitel ® HT for air ducts

Arnitel ® HT increases the long-term working temperature of high temperature resistant TPC to 175 ° C and the peak temperature to 190 ° C. DSM uses the Arnitel ® HT TPC material solution to help automakers create an extremely innovative integrated flexible heat booster tube and realize a one-step production process, which not only greatly improves production efficiency, but also reduces production costs by about 50 %, A weight loss of 40%. At the same time, the risk of deformation, leakage and disengagement of the hot supercharger tube during engine operation is greatly reduced, bringing a new standard of flexible supercharged hot air intake pipe to the automotive industry.

Stanyl ® and Akulon ® for turbine components

Stanyl ® can maintain its high rigidity at high temperatures up to 160 ° C, so it is very suitable for high temperature, high performance and high torque transmission applications. Its performance in this application is better than PPA , PA6T , PA9T , usually also Better than PPS and LCP ;

Xytron ® is used for cooling pump impeller, etc.

Xytron ® is a high-performance plastic compound based on polyphenylene sulfide. Xytron ® provides extreme chemical resistance, dimensional stability, inherent flame retardancy, high stiffness, glass transition point (90 ° C), continuous use temperature 240-260 ° C (reduction), melting point 280 ° C. For many different applications, all excellent properties contribute to excellent performance.

Akulon ® Fuel lock is used in CNG / H2 tank (pressure tank, hydrogen tank)

Akulon ® Fuel lock PA6 is lined with CNG-IV compressed natural gas cylinders, making it possible to make smaller, smarter, safer, and more effective automotive cylinder systems, eliminating A major obstacle.

Scan the QR code to read on your phone

Page Copyright - Jiangsu Taiyi Plastic Technology Co., Ltd. 苏ICP备2020070769号-1 Powered by www.300.cn