NEWS CENTER

Specially developed and developed high-end polyoxymethylene (POM) / long-fiber materials (PP.PA.TPU, etc.) in automobiles, electronic appliances, fasteners, sanitary, military, aerospace, marine, office supplies, agricultural irrigation, electronic appliances, etc.

DSM Akulon ® Ultraflow - belongs to PA6's "natural"

- Categories:Media coverage

- Author:

- Origin:

- Time of issue:2018-12-13 09:39

- Views:

(Summary description)DSM Akulon® Ultraflow is an easy-to-process PA6 . Compared with ordinary PA6, the flowability is increased by 80%, and the...

DSM Akulon ® Ultraflow - belongs to PA6's "natural"

(Summary description)DSM Akulon® Ultraflow is an easy-to-process PA6 . Compared with ordinary PA6, the flowability is increased by 80%, and the...

- Categories:Media coverage

- Author:

- Origin:

- Time of issue:2018-12-13 09:39

- Views:

DSM Akulon® Ultraflow is an easy-to-process PA6 . Compared with ordinary PA6, the flowability is increased by 80%, and the injection molding cycle is shortened by 40% without affecting the mechanical properties of the material.

Akulon® Ultraflow is used in many demanding products, such as engine hoods, intake manifolds, automotive exterior mirror housings, furniture and power tools. The meaning behind Akulon® Ultraflow's faster flow is not only through faster cycle times, but also the reduction of system costs.

Akulon® Ultraflow application advantages:By achieving thinner wall thickness and requiring less material, engineers can gain more design freedom; more mold cavities means lower production costs; on lower tonnage machines Molded parts can increase manufacturing flexibility. Improve the appearance of the surface while reducing the need for paint; the range of replaceable metals is expanded, the weight of the product is reduced, and the fuel and carbon are reduced correspondingly for automobiles.

Surface appearance

Akulon® Ultraflow compared with ordinary PA6, Akulon® Ultraflow provides a better surface appearance, reducing secondary surface treatment processes such as painting processing, component removal and so on. In addition,the surface appearance of parts made of Akulon® Ultraflow 50-60% glass-reinforced grades is similar to that of ordinary 30% glass-reinforced PA6. Under the condition of similar surface appearance, Akulon Ultraflow material adds more reinforcing materials. This excellent surface appearance is especially suitable for making thin-walled parts with high strength requirements.

Replace metal and plastic

The introduction of Akulon UltraflowK-FHG0 and Akulon UltraflowK-FHG12 significantly reduces the cost of metal replacement and provides a huge opportunity for metal replacement. The weight and noise reduction achieved byAkulon® Ultraflowcontributes to the development of the entire value chain.

Akulon® Ultraflow also offers the option of replacing high-temperature thermoplastics, which can provide greater design freedom and can combine higher glass loads with thinner wall sections to achieve the same stiffness and dimensional integrity.

Akulon® Ultraflow can also replace 30-40% glass fiber filled PPS or aromatic polyamide, these products provide stiffness and / or appearance applications at operating temperatures above 100 ° C, thereby saving costs.

At a certain temperature, Akulon UltraflowK-FGH0 or K-FGH12 can provide a harder, stronger, and more attractive appearance than expensive engineering plastics.

Automotive applications-oil pan

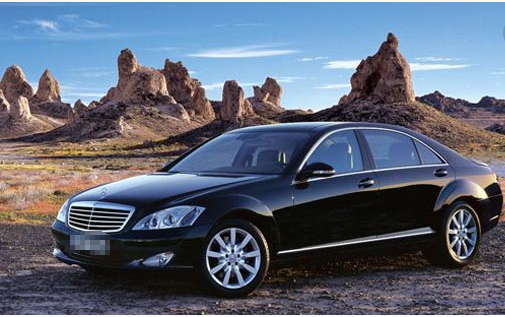

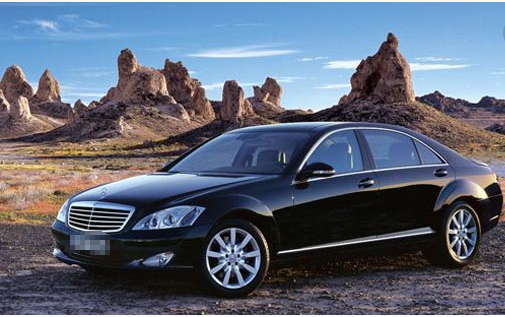

Especially in the field of metal substitutes, Mercedes and DSM's first-class customer BBP, Kunststoffwerk Marbach Baier has proved this point. The new Mercedes S-Class uses DSM ’s unique Akulon® Ultraflow PA6 breakthrough oil pan: while meeting various performance standards, its weight is 50% lower than its metal weight. Meeting the extreme performance requirements of the oil sump is a challenge that DSM and Akulon® Ultraflow meet positively: this unique high-flow, oil-resistant, fiberglass-reinforced polyamide releases our customers major processing and performance advantages-no Will affect the mechanical properties.

For Mercedes S-Class cars, DSM's research team worked closely with BBP in Germany to conduct a series of demanding application tests on the Akulon® Ultraflow oil pan. Akulon® Ultraflow oil pans have all reached the application level and are now in production. DSM believes that when more manufacturers see the benefits it can bring, they will use this technology. The rapid flow of Akulon® Ultraflow is not only equivalent to faster cycle time and less warpage; but because the material can make the wall thickness thinner, it means that less material is needed-which in turn provides engineers with more Design freedom.

Future prospects: one-piece oil pan system

In the next few years, DSM expects to see the introduction of a hybrid oil sump, integrated with the structurally loaded bottom plate, to carry the load from the transmission system, and it is expected that the entire module will be made entirely of thermoplastic components and connected together using vibration welding technology .

Automotive applications- MPC engine cover

Akulon® Ultraflow is glass and mineral reinforced PA6 with excellent fluidity and low warpage.

Akulon® Ultraflow is DSM's glass and mineral-reinforced PA6 with excellent fluidity and low warpage. It provides a variety of advantages for an increasing number of automobile hood manufacturers, including American automotive experts Micro Precision Parts (MPC).

Every manufacturer wants products with excellent processing characteristics, minimal warpage and excellent surface appearance. Akulon® Ultraflow provides compliance with all MPC standards. MPC chose Akulon® Ultraflow K-FHGM24 (10% glass fiber reinforced material containing 20% mineral filler) because it can produce warped parts that are much lower than other glass fiber reinforced mineral filled nylon. This leads to significant costs, mainly because the anti-warpage cooling device is not required immediately after the molding process.

Akulon® Ultraflow's faster flow rate also shortens the cycle time of the MPC plastic bonnet, further reducing system cost. And because this material can reduce the wall thickness by up to 20%, less material is required to produce parts, thus giving engineers more design freedom. The combination of the material's outstanding mechanical properties and outstanding aesthetic properties prompted MPC to start consideringwhether Akulon® Ultraflow can now be used in other traditional production parts.

Scan the QR code to read on your phone

Page Copyright - Jiangsu Taiyi Plastic Technology Co., Ltd. 苏ICP备2020070769号-1 Powered by www.300.cn