NEWS CENTER

Specially developed and developed high-end polyoxymethylene (POM) / long-fiber materials (PP.PA.TPU, etc.) in automobiles, electronic appliances, fasteners, sanitary, military, aerospace, marine, office supplies, agricultural irrigation, electronic appliances, etc.

In-depth understanding of PA6, PA66

- Categories:Industry news

- Author:

- Origin:

- Time of issue:2018-12-20 09:32

- Views:

(Summary description)PAIt is one of the common engineering plastics, and PA6 and PA66 are the most common nylon materials...

In-depth understanding of PA6, PA66

(Summary description)PAIt is one of the common engineering plastics, and PA6 and PA66 are the most common nylon materials...

- Categories:Industry news

- Author:

- Origin:

- Time of issue:2018-12-20 09:32

- Views:

PAIt is one of the common engineering plastics, and PA6 and PA66 are the most common nylon materials. The two have similar structures and have a lot in common, so what is the difference between the two? Let's take a look today with the editor.

1. Background

PA66 is a PA66 polymer which wassuccessfully polymerized with adipic acid and hexamethylenediamine by Carothers in 1935. The process ofmaking PA66 by melt spinning was discovered from 1936 to 1937, andcommercialization was completed by the American DuPont company at the end of 1939.

PA6 is a PA6 polymersynthesized by Schrack of German IG company in 1939. Using caprolactam as the starting material and ε-aminocaproic acid as the initiator, it was heated. PA6 fiber production began in 1939 and was commercialized by French companies in 1943.

2. Structure

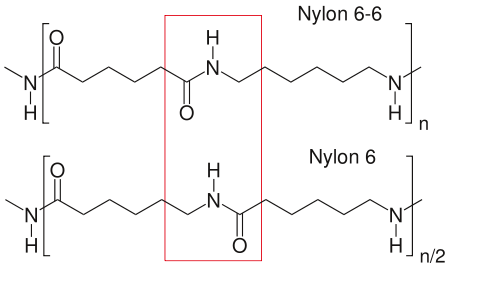

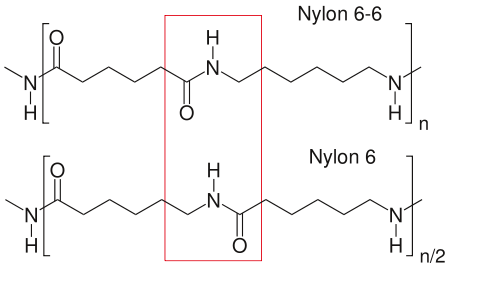

In order to analyze their differences, we need to start with their structure. As we all know, nylon PA66 is formed by polycondensation of adipic acid and hexamethylenediamine. The molecular formula of PA6 is the same as PA66, but its structure is different, as shown in the figure below:

3. Performance

The performance difference between PA66 and PA6 is as follows:

Mechanical performance, thermal medium performance, price, melting point and other properties PA66 are greater than PA6 ;

However, PA66 is lower than PA6 in water absorption, weather resistance, condensation time and molding performance .

4. Process conditions

Drying

PA6 is easy to absorb moisture. Special attention should be paid to drying before processing. If the material is provided in waterproof packaging, the container should be kept closed. If the humidity is higher than 0.2%, it is recommended to dry in hot dry air above 80 ℃ for 3-4 hours. If the material is exposed to air for more than 8 hours, it is recommended to vacuum dry at 105 ℃ for more than 1-2 hours. It is best to use a dehumidifier.

If the PA66 is sealed before processing, then there is no need to dry it. If you open the storage container, it is recommended to dry in hot dry air at 85 degrees Celsius. If the humidity is greater than 0.2%, it needs to be vacuum dried at 105 ℃ for 1-2 hours. It is best to use a dehumidifier. Molding temperature: 260 ~ 310 ℃, 280 ~ 320 ℃ means enhanced varieties.

Mold temperature

PA6 : 80 ~ 90 ℃. Mold temperature significantly affects the crystallinity, which also affects the mechanical properties of plastic parts. For thin-walled plastic parts with long process flow, it is recommended that the mold temperature is higher. Increasing mold temperature can increase the strength and rigidity of plastic parts, but reduce toughness. If the wall thickness is greater than 3mm, it is recommended to use a low-temperature mold at 20-40 ° C. For glass reinforced materials, the mold temperature should be higher than 80 ° C.

PA66 : 80 ℃ is recommended. The mold temperature will affect the crystallinity, which will affect the physical properties of the product. For thin-walled plastic parts, if the mold temperature is below 40 ° C, the crystallinity of the part will change with time. In order to maintain the geometric stability of the part, annealing treatment is required.

Melting temperature

PA6 : 230 ~ 280 ℃, 250 ~ 280 ℃ for reinforced varieties.

PA66 : 260 ~ 290 ℃. The product for glass additives is 275 ~ 280 ℃. The melting temperature should be avoided above 300 ℃.

Injection pressure

They are generally between 750 ~ 1250bar (depending on the material and product design).

Injection speed

Both are high-speed (slightly reduced for reinforced materials).

Runner and gate

Because the setting time of PA6 and PA66 is very short, the gate position is very important. The gate diameter should not be less than 0.5 * t (where t is the thickness of the plastic part). If a hot runner is used, the gate size should be smaller than the conventional runner, because the hot runner can help prevent premature curing of the material. If submerged gate is used, the minimum diameter of the gate should be 0.75mm.

5. Application

PA6 engineering plastics have the advantages of high tensile strength, good impact resistance, wear resistance, chemical resistance, and low friction coefficient. Through glass fiber modification, mineral filling modification, and addition of flame retardant, it can make its comprehensive performance more excellent. Mainly used in the automotive industry and electrical and electronic fields.

PA66 has the advantages of high strength, good rigidity, impact resistance, oil resistance, chemical resistance, wear resistance, self-lubrication, etc., especially hardness, rigidity, heat resistance and creep properties. Because PA66 has higher strengththan PA6 , it is more used in the production of industrial yarns, such as cords.

Scan the QR code to read on your phone

Page Copyright - Jiangsu Taiyi Plastic Technology Co., Ltd. 苏ICP备2020070769号-1 Powered by www.300.cn